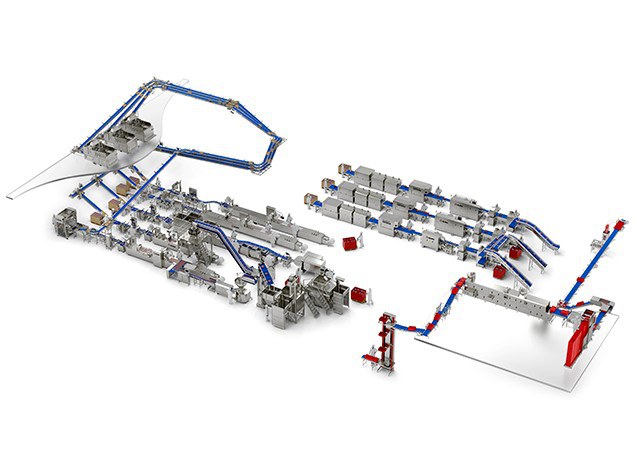

Complete solution for meat product packaging

The complete automation solution for the packaging plant includes eight packaging lines for different meat products. Industrial cuts vacuum packed with Flow-Vac® technology and other case ready products for retail such as portioned meat, minced meat and filleted in different vacuum and MAP packages with thermoforming technology. It is a plant in which the packaging machines have been integrated with previous meat preparation systems, case erectors, plastic crates washing, box distribution and logistics, weighing & labeling equipment, quality control and automatic boxing.

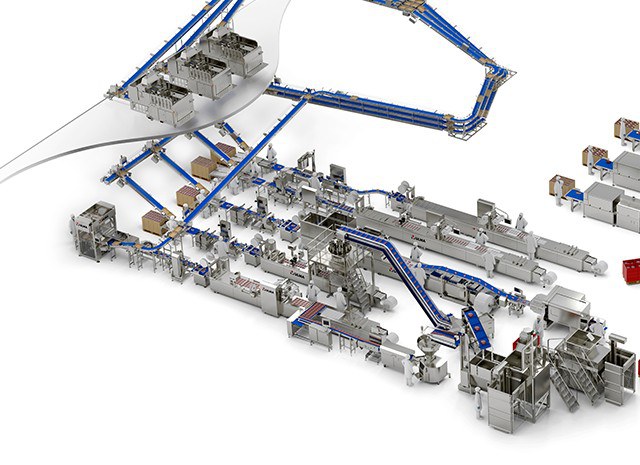

Three packaging lines for industrial cuts of meat that, after labeling, are vacuum packed using the ULMA Flow-Vac® system. The system produces in real time the bag adjusted to the length of each piece and introduces it automatically, thus reducing the consumption of the packaging material, the risk of contamination by handling and the number of leaks and reprocesses.

These lines are complemented with vacuum chambers for closing and sealing the bag to later improve the presentation by passing through retraction ovens that give the package second skin appearance.

Five thermoforming packaging lines adapted to the different pieces of meat to package both under vacuum and in a modified atmosphere. In these five lines, whole pieces of fresh meat are vacuum packed, fillets and minced meat in rigid packages in a modified atmosphere (MAP).

The lines are complemented by integrated preparation equipment, cutting machines and even automatic loading equipment as well as automatic weighing & labeling equipment and metal detectors.

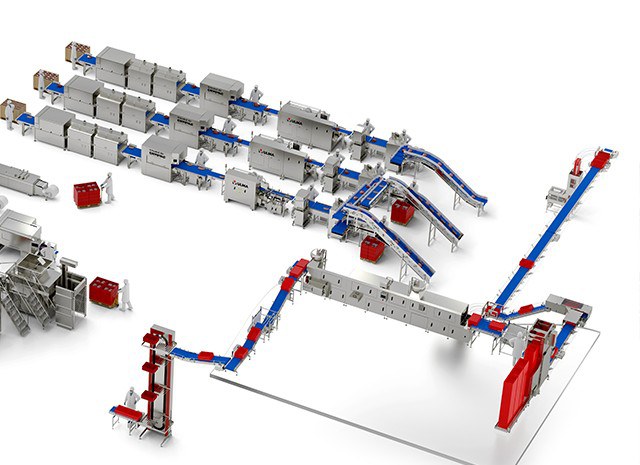

There is a carton case forming room with three automatic forming machines that is located on the upper floor. These case erectors are multi-format and distribute the boxes through a transport system to the end of lines situated on the lower floor.

The automatic end of lines have a robot based case packers that allows handling 96 boxes/min per line. These equipments have great flexibility allowing to make different mosaics depending on the products. In addition and prior to packing, a batch collector is made at the exit of the machine, to improve the traceability of the products in the production process.

Transport system to collect the customer' s slave boxes from production lines and transfer it to the washing machine. For this purpose, there is a lift system to elevate the crates to the upper floor where the washing area is located.

At the exit of the washing machine and depending on the needs of the production lines; clean crates are transported back to production lines using crate lowerators, or they are accumulated in a buffer with an automatic stacker that stacks piles of empty crates. These piles are accumulated for later consumption on the production lines when necessary.