ULMA Designs New Entry-Level Automation Solution for Bakery Sector

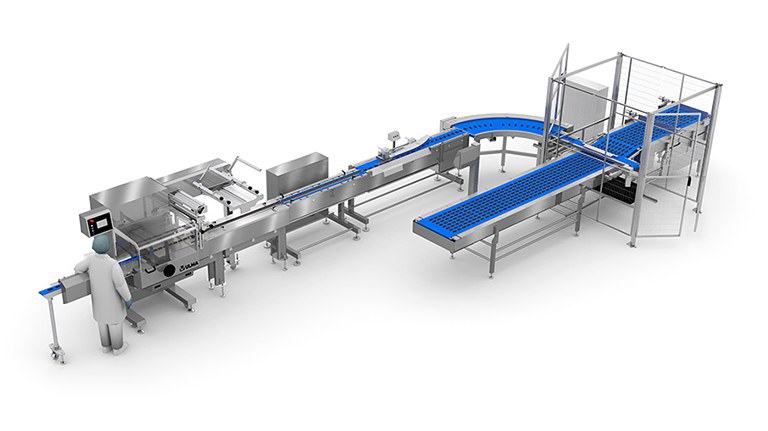

In response to an increase in SME bakery businesses seeking ways to integrate automated solutions to improve speed and drive cost-efficiencies on the packaging line, ULMA Packaging UK has designed a new entry-level automatic line with a reduced layout.

The line has been designed with SMEs in mind, to save space on the factory floor and reduce manual handling. To do this, ULMA has designed the line to include a receiving conveyor, to automatically sort bakery products ready for even and continuous row distribution using a drop-down transfer conveyor. Products can also be accumulated to allow for short breaks in production, with automatic re-feed, or can be rejected for various product fault conditions.

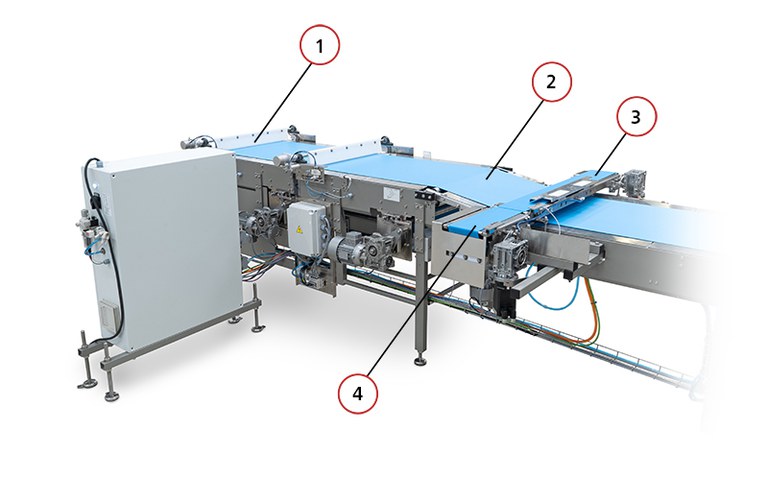

The new multi-conveyor system has been designed to a reduced size in order to achieve a more compact line. In addition, the system is designed with ease of change of conveyor belts in mind, optimising maintenance and cleaning time.

Using the proposed automation line solution with ULMA’s compact FR 200 Horizontal Flow Wrapper (HFFS), the line has been shown to be highly flexible and versatile across a variety of product sizes. Using the FR 200, this flow wrapper is equipped to work with sustainable film, which is increasingly important for the bakery sector to be able to implement ways to reduce environmental impact.

MAIN BENEFITS

- Small layout

- Highly flexible

- Equipped to use sustainable film

- Remote connection

- Product receiving conveyor

- RDS-DT 0 row distributor with swivel conveyor

- Product row removal conveyor at 90º

- Conveyor that fills gaps between products

Steve Craddock, Business Manager for Automation Projects at ULMA, says: “The benefits of automation have long been known, but for many SMEs in the bakery sector who are still unsure of whether automation is a possibility, especially for smaller packaging lines, it was important for us to show this market the possibilities. As a result, ULMA has responded with a newly designed automation solution that is easy to integrate into existing lines and which is both compact and efficient.

“When combined with ULMA’s FR 200 HFFS, the benefits continue with even more flexibility and ability to cope with packaging a variety of different products, alongside its sustainability credentials and compatibility with easy to recycle films.” For more information, please contact us.