TFS 80 hygienic design thermoformer

Hygienic thermoforming machine for flexible film with modified atmosphere (MAP) and vacuum options. The minimal space for a hygienic thermoformer.

The TFS 80 Is a thermoforming machine designed to pack food, non-food or medical products. The package is created directly by the machine using two rolls of film.

The TFS 80 offers the ideal way to advance from manual packaging to automatic packaging. These machines provide an economical solution with the same cost saving advantages of larger thermoforming machines:

- Reduced package cost.

- Increased productivity.

- Improved product appearance.

- Faster product loading.

The machine characteristics make it highly desirable for mixed production requirements, since formats can be easily changed to meet the needs of the customer. It’s versatility, easy operation, and quick size change also make it suitable as a support machine for short run products.

Like all other ULMA machines, the priority in design is given to:

- Highest quality commercial components.

- In accordance with international safety standards.

- Easy sanitation IP-65 compliance.

- Easy change of dies and tooling.

- Easy access for maintenance.

- Ease of operation.

- Basic 1670 mm. frame.

- Bottom and top reel holder.

- Standard basic forming (forming by air) and sealing die.

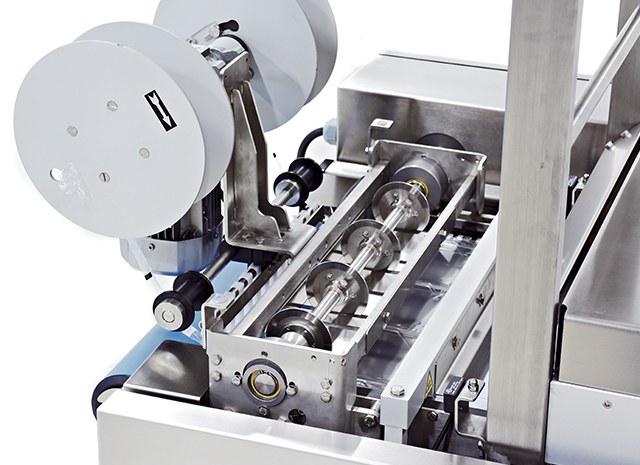

- One transversal cutting system.

- Motorized longitudinal cutting system

- Pneumatic safety bars.

- Exit ramp.

- Film scrap collector.

- Vectorial inverter.

- 2 user manuals.

- Inox. covers.

- UPC control.

- Touch screen color control panel of 7”.

- Hygienic frame TFS.

- Adaptation for different formats.

- Vacuum and gas system.

- Integrable vacuum pump 40,63 or 100 m3/h ( to be defined).

- Pneumatic change of the sealing plate.

- Adaptation of the sealing plate for easy-open corner.

- Zig-zag knife for transversal cutting.

- Pneumatic longitudinal cutting system.

- Printed film centering device.

- Aspiration system scrap collector.

- Exit belt.

- Synchronization with peripherals.